Scientists in China have recently developed an aluminum alloy with unprecedented strength and thermal resistance, Chinese media reports.

Aluminum is commonly used in constructing aircraft, vehicles, and space equipment due to its lightweight nature and affordability. Moreover, this material is renowned for its robustness and resistance to corrosion, rendering it ideal for aircraft manufacturing.

Aluminum Alloy with Unprecedented Thermal Resistance

Researchers at China's Tianjin University have developed a brand-new method for producing aluminum alloy that improves the material's previously lacking resistance to extreme heat.

According to reports, this innovative aluminum alloy can maintain functionality at temperatures exceeding 400 degrees Celsius, significantly improving from its typical breakpoint temperature of 350 degrees Celsius.

READ NEXT : US Report Says BMW, Jaguar, and Volkswagen Used Illegal Chinese Parts With Links to Child Labor

Aluminum Alloy Production Breakthrough

The scientists achieved this feat by incorporating nanoparticles into conventional aluminum alloys.

They claim that this process has granted the material a tensile strength of 200 megapascals, six times stronger than most aluminum variants available when subjected to temperatures of up to 500 degrees Celsius.

This novel process for producing aluminum alloy holds promise for various Chinese manufacturing, transportation, and aerospace sectors, with researchers highlighting its simplicity, cost-effectiveness, and scalability for industrial production.

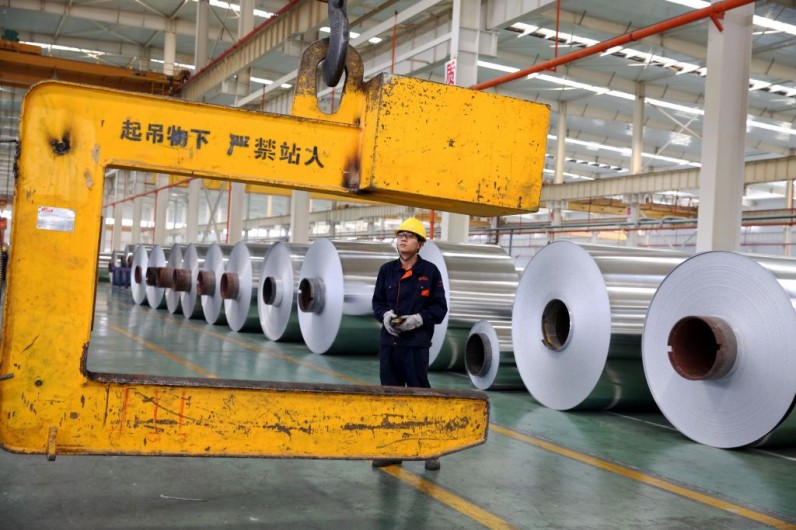

Data indicates that in 2023, China produced approximately 4.1 million metric tons of aluminum through smelting operations.

According to one of the researchers, the team is collaborating with leading industry experts and research institutions to advance the development of heat-resistant aluminum alloys for aerospace engines and critical components.

They anticipate that the material will soon find applications in industrial settings.

The research findings were published in Nature Materials on April 26.

Join the Conversation